Challenge

The customer had semi-automatic machines for filling and capping oil bottles. Due to growing demand, available capacity (2700 pcs per shift) was insufficient to satisfy needs. The customer also had a problem with filling reliability.

The request was to manufacture a machine capable of filling, capping, and labeling 10000 10ml bottles in one 7.5h shift.

The machine also needs to be compact so that the technologist can enter its manufacturing space.

SOLUTION

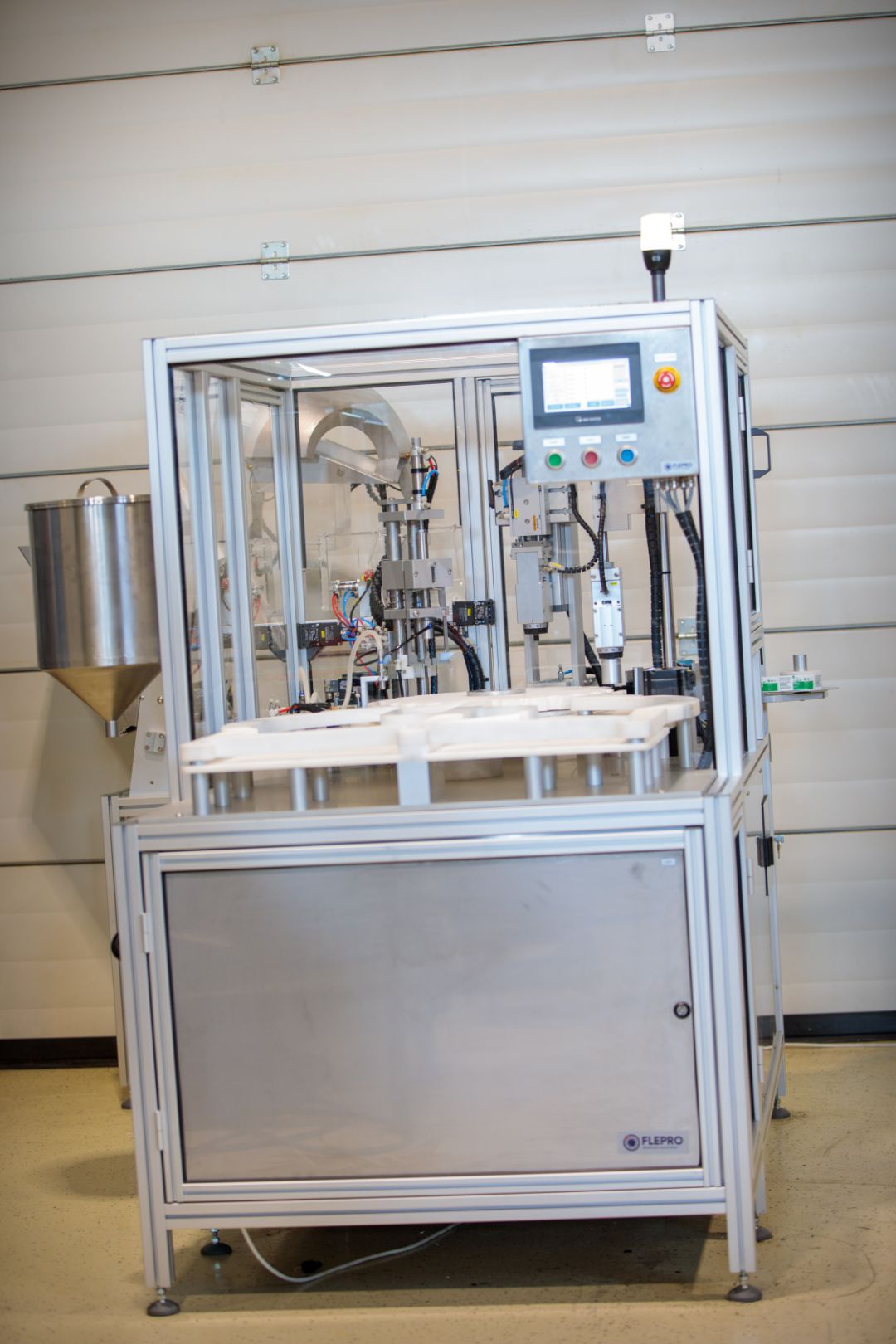

The machine is compact and comes in two variants:

- without the elevator dimensions 1700 x 1050 x 1700

- with an elevator dimensions 2200 x 1600 x 1820

The capping system contains an elevator with the vessel into which droppers are poured.

The elevator automatically lifts and leads them to the control system. In case of dropper rupture, the dropper is ejected into the scrap box.

If the dropper cap is intact, it is inserted into a filled bottle. After that, the bottle is capped, and the labeling system labels the bottles. At the end of the process, the bottles are collected at the exit part of the rotating entry & exit table.

Mechanical parts are made of stainless steel, anodized aluminum, and plastic POM C.

BENEFITS

We have delivered the high-end specialized machine to the customer, with the appropriate production capacity, precise engineering, filling reliability with dropper cap quality check.

Photo Gallery

© 2021 FLEPRO d.o.o.